VISI takes centre stage with LAG guitars

VISI takes centre stage with LAG guitars

LAG is a leading maker of musical instruments. Founded in 1978 by Michel LAG Chavarria in Toulouse, the company started to make a name for itself after setting up its workshop in Bédarieux, a small town in the hills of Roussillon in the south of France. Since signing a deal with market powerhouse Algam, France’s number one musical equipment dealer, the guitar maker has expanded its customer base far beyond its homeland and now enjoys worldwide recognition.

Thousands of guitarists throughout the world — amateurs and rock legends alike — play LAGs. References include top French singers Kyo, Jean Felix and Francis Lalanne, Yael Naim, and international stars such as Keziah Jones, Jean Michel Jarre, Stéphane Sanseverino, and cult rock bands like Trust, Motorhead and Cradle of Filth.

"We spend less time on surface finishing because the machining is so precise. The point distribution is very even and the result is a smooth toolpath.”

Etienne Réau

The company has fourteen staff still designing and building its high-end guitars in the original workshop and further plants in China and South Korea turning out high-quality instruments at more competitive prices, based on prototypes conceived and crafted in Bédarieux.

As the brand has set out to conquer much bigger markets in recent years, LAG has looked for ways to update its approach to design and manufacturing. The company decided to invest in the latest technologies to enable them to reduce time-to-market for its latest models and ensure it maintained its reputation as a creator of exclusive guitars, using rare woods with luxurious finishing and sharp styling.

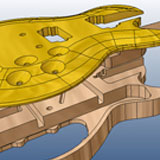

The company invested in a custom built CNC machining centre from Créneau Industriel that enables them to machine several guitars simultaneously, and in the latest CADCAM technology from Vero Software to help with the design and manufacture.

Etienne Réau, CNC manager explains that they selected VISI for both technical and economic reasons. LAG were looking for intuitive CADCAM system with both 2D and 3D machining capabilities, and a supplier that would provide local support as the new working methods were phased in. Vero France was on hand to develop the Num 720 post-processor and provide training and consulting services allowing LAG to reproduce the machine setup and NC programs in such a short period. Réau explains: “Our aim was to develop the ability to respond more quickly to customer enquiries, and build prototypes with a shorter lead-time, without sacrificing the levels of quality and creativity that were the basis of the company’s reputation. This has been achieved and one key factor is that we now machine 4 bodies and four necks at the same time on our CNC router. This considerably reduces handling times and enables us to get on with other concurrent operations.”

In the eighteen months since VISI was introduced, LAG has produced over 500 NC program files and the software has had a major impact on the company’s working methods. The guitars are designed in a matter of hours and the musician or sales department can get an immediate, detailed idea of what the instrument looks like. This provides a solid basis for either approving or requesting modifications to the design. Since the company invested in a rapid prototyping machine, it is even possible to watch the guitar being made. The CADCAM system being used; VISI is a hybrid solid & surface modeller based on the robust Parasolid kernel and fully supports the construction of curved or sculpted surfaces for ergonomic and creative guitar design. VISI Machining, a HSM oriented CAM solution is used to produce optimised 2 axis and 3 axis toolpath data for the CNC router.

The Chinese-built guitars are also designed with VISI and, as soon as the prototype has been approved, the drawings or models are sent to the Chinese plant for production. To further optimise production, Réau also set out to find ways to reduce handling operations. Turnaround time between operations is now faster and the tooling use has been standardised with the use of Ballnose mills instead of special tools. The combination of efficient toolpaths and excellent post-processor debugging have enabled program optimisation and highly competitive 3D machining performance.

In terms of quality, the results have been excellent explains Réau: “We spend less time on surface finishing because the machining is so precise. The point distribution is very even and the result is a smooth toolpath. Our complex surfaces come out great first time with an excellent surface finish. The direct consequence is that we save time on finishing passes and a lot of money on the abrasives we use for sanding, not to mention the environmental advantages.”

Concluding Réau says “We are fortunate to be working in a niche area with such high added-value. LAG has built up a very special know-how over the years and we have combined this with hi-tech resources. We are now in a position to meet the demands of artists faster than ever, while remaining financially attractive. Not only have we maintained our anchorage in Bédarieux, but we have been able to demonstrate, every day, that our production methods are in line with the company’s international ambition.”

About The Company:

Name: LAG Guitars

Web: www.lag.fr

Benefits Achieved:

- Single product environment for guitar design & manufacture

- Smooth point distribution & HSM toolpaths running Créneau Industriel CNC router

- Machining 4 bodies and 4 necks at the same time on CNC router

"We spend less time on surface finishing because the machining is so precise. The point distribution is very even and the result is a smooth toolpath.”

Etienne Réau