Design benefits filter through

Design benefits filter through

With the Mould & Die industry being squeezed by Eastern European and Asian markets, the 'right’ CAD/CAM solution is an increasingly key factor for success. Gebr. Schwarz GmbH have been using VISI from Vero Software since 2000 and have found that the costs and quality were so favourable, the plastic moulding company now requires all of its external designers to use VISI for joint projects.

Located in Rottweil-Neukirch, Gebr. Schwarz GmbH has been providing solutions, from development to serial production, to the plastic injection moulding sector since 1966. The company is a global player in the production of injection-moulded plastic parts for the information technology, automotive, environmental, energy, medical and electrical sectors. The company has established its excellent reputation by offering exceptional quality parts and specialist technical know-how.

"Our experience shows that the software is flexible enough to implement changes more rapidly than with any other system providing the maximum possible time frame for a corrective solution.”

Andreas Artmayer

Gebr. Schwarz GmbH had already implemented 3D tool design in 1995 but recognised the limitations of generic CAD/CAM systems for complex tooling. Karl-Heinz Mutschler, Manager of IT, QA and Marketing, stated: “Our market analysis and bench mark tests showed that VISI was the optimal system with dedicated functions for tool & die. One of the main advantages is the quality and variety of data import options. During our bench mark period, VISI scored highest in a data import and manipulation test for a large component. It was more tolerant towards faults in external data. Our company currently handles approximately 1,000 tools per year and a data volume of several gigabytes per month, so it was imperative that we have import reliability.”

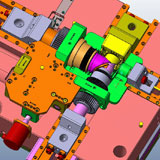

Shortly after the initial trial period, a second VISI workstation was added and, after that, the number of VISI systems in use has grown continuously in parallel with the number of machines. Currently, Gebr. Schwarz GmbH is utilising eleven VISI stations, two data viewers and, in addition to CAD, VISI Mould, VISI Analysis, VISI Electrode and VISI Machining are all also being used. Karl-Heinz Mutschler noted that “VISI has repeatedly given our design department an advantage in the development of our tooling. The reason may be that the software is perfectly tuned to the needs of tool-makers.”

The benefits of VISI were highlighted in a recent project for a freshwater filter supply system, in which the software was used extensively from the beginning. Traditionally, certain parts would be made from cast brass, as the system must withstand dynamic pressure up to 21 bar and static pressure up to 48 bar. Raw material supplier VTS Plastics GmbH suggested the use of Grivory GV4H, a 40% glass-fibre-reinforced plastic. The customer had already performed FEA calculations and wanted to know how the component had to be modified to be suitable for tooling and production and to withstand the necessary pressures.

An internal filling analysis to determine the filling behaviour was performed to detect possible air traps and weld lines. The position of the weld lines were of particular importance in this case, as they are potentially a weak point under high pressure. A further challenge was posed by the differential shrinkage properties of the material. For instance, the sealing rings had to be absolutely watertight, with an accuracy of two hundredth of a millimetre. A perfect circle was required in the component, which was finally achieved by a complex egg-shape in the tool. Andreas Artmayer, Design Manager at Gebr. Schwarz GmbH, remembers: “The complex geometry and tight delivery schedule was a serious challenge for our project team. We only had half a year to bring the project to serial production and this would certainly not have been possible without the help of VISI. A component of this complexity requires three to four optimisation cycles. During this project, all parts that had not been designed with VISI were internally converted.”

Given the performance of VISI throughout the project and the high degree of customer satisfaction, it is not surprising that Gebr. Schwarz GmbH plans to extend its VISI portfolio in the near future. Future projects involve 5-axis simultaneous milling and a completely new development for die sinking, which can transfer electrode data from VISI Electrode directly to the die-sinking machine.

Gebr. Schwarz GmbH. is so happy with the performance of VISI and its technical support that they recommend VISI without hesitation to all their external designers. All partners who work in the design field for Gebr. Schwarz GmbH now requires an up-to-date VISI workstation. An analysis of the filter system project clearly showed that the production of tools designed with VISI are up to 10 percent more cost-effective than that of other tools.

Andreas Artmayer concludes: “This made it clear to us that all future designs must be produced using VISI. Our experience shows that the software is flexible enough to implement changes more rapidly than with any other system providing the maximum possible time frame for a corrective solution. VISI was, and is the right solution for us.” It is, therefore, not surprising that Gebr. Schwarz GmbH has never regretted its commitment to 3D tool design and VISI.

About The Company:

Name: Gebr. Schwarz GmbH

Web: www.schwarz-gmbh.de

Benefits Achieved:

- Dedicated functions for tool & die

- Single environment for tool design, electrode extraction, detailing & CAM

- Tools designed with VISI are upto 10% more cost-effective than that of other tools

"Our experience shows that the software is flexible enough to implement changes more rapidly than with any other system providing the maximum possible time frame for a corrective solution.”

Andreas Artmayer