Machining STRATEGIST utilizzato per una ricerca nell'Università del Sussex UK

A university student used Machining STRATEGIST from Vero Software to undertake new research into combining tool sequences with the use of multi-objective optimisation of cutting parameters. His research created a system that can provide manufacturers with greater information and a more flexible machining environment, depending on the individual needs of a particular job.

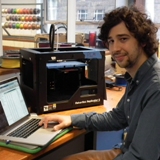

The main focus of Alexander Churchill’s PhD research at the University of Sussex was optimising tool sequences and machining parameters for rough milling operations, while maintaining low search times. Using Machining STRATEGIST he created ways of using fewer constraints than previous approaches, while supporting more realistic tool libraries.

“Multi-objective optimisation refers to the simultaneous optimisation of several objectives. A classic example of where several considerations are used to assess a potential solution is time and cost. The cheapest solution probably won’t be the fastest, and vice versa, so it would be useful for the user to have a selection of solutions showing optimal trade-offs.”

While existing research has applied these trade-off techniques to optimise machining parameters, Alex says he is the first to take this approach to tool selection. “The choice of tools used in a roughing operation greatly affects the machining process, so it’s important to optimise the tool sequence as well as machining parameters.

“My research came up with the first system to optimise both simultaneously, which could have many uses in industry, giving manufacturers more choice and flexibility through a larger range of solutions.”

He says although his work is a first step, it paves the way for CAD/CAM software to take a number of objectives such as total machining time, total tooling costs and total manufacturing costs, and then provide several different solutions for a machining process giving optimal trade-offs. “Managers can then choose the solution that best meets the individual situation. If faced with a long queue of jobs they may choose a more expensive but faster option; while for a lighter job load they could go with a longer but cheaper solution.”

Machining STRATEGIST Development Manager Steve Youngs says Alex’s multi-objective approach to multiple-tool selection has highlighted how using a combination of tools can minimise the remaining stock on the part while also minimising machining time and wear on the cutter. “While his research is academic and theoretical at this stage, it has enormous potential benefit for many industrial processes. With Vero’s VISI software, for example, it could be used to determine optimum plastic mould flow values.”

Vero joined forces with Alex after agreeing to fund an Engineering and Physical Sciences Research Council industrial research project. Steve Youngs modified Machining STRATEGIST enabling Alex to process 80,000 tests a day, measuring the total excess stock produced by a given tool sequence, and provided him with a Python interface for use with the optimisation algorithms.

Alex says: “Machining STRATEGIST was very important for my research because it supports tool sequences containing combinations of many different cutters. I was able to use tool libraries that contained flat end mill, ball nose and toroidal cutters...while many researchers have concentrated only on flat end mill tool types.”

He also carried out research on the use of parallel computing to speed up the optimisation process even further, and says Machining STRATEGIST was invaluable for that work, too, as he was able to run it on multiple machines with very little set-up. “This enabled me to create a network of machines processing solutions on the computing cluster at the University of Sussex as well as on the Cloud.”

Alex has published his findings in two papers: “Multi-Objective Tool Sequence and Parameter Optimisation for Rough Milling Applications” and “Tool Sequence Optimisation using Synchronous and Asynchronous Parallel Multi-Objective Evolutionary Algorithms with Heterogeneous Evaluations,” jointly with his university supervisors Phil Husbands and Andrew Philippides.

He has now taken up a research post at Queen Mary University of London, investigating techniques for developing autonomous learning in robots.